DC programmable load

The latest gadget we’ve got in the works here is a modular DC programmable load.

The idea is simple: take a bunch of mosfets, some opamps and a DAC and you’ve got yourself a massive power hog.

Our design uses relatively cheap irfp260 mosfets instead of special(and expensive) linear rated fets. The ideea is to downrate them enough so they don’t blow up and still be economical compared to the specialty linear fets. We use 8 IRFP260s with each having their own feedback loop using 0.1ohm sense resistors and an opamp. The opamps are driven by a 12bit DAC which is driven by an STM32F103.

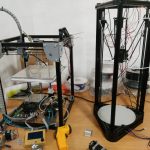

In the pictures you can see the prototype build which is basically just a big heatsink with the control board riding on top of it. The control board has connectors for daisy-chaining more modules and also a connector for hooking up a user interface board – which is the next thing that needs to be built for this proto…

So far I’ve tested this build using a 24V 10A power supply i had lying around and it didn’t break a sweat. The maximum design ratings are 500W@100V or 500W@40A…I’ll have to see if I can get something together to stress test this thing at max load.